ROBOTIC ARM DESIGN

|

fig1.1: 6-AXIS ROBOTIC ARM |

- INTRODUCTION& PROJECT FORMULATION

- PROJECT DESIGN

- DEVELOPMENT AND IMPLEMENTATION

- CONCLUSION AND SCOPE

now we will try to understand every part one by one so let's start

INTRODUCTION AND PROJECT FORMULATION

1.1 Overview

A robotic arm is a type of mechanical arm, usually programmable, with similar

functions to a human arm; the arm may be the sum total of the mechanism or may be part of

a more complex robot.

The links of such a manipulator are connected by joints allowing either rotational

motion (such as in an articulated robot) or translational (linear) displacement. The links of the

manipulator can be considered to form a kinematic chain. The terminus of the kinematic

chain of the manipulator is called the end effector and it is analogous to the human hand.

1.2 Some types of Robot in market

|

| fig1.2:SCARA Robot |

1.3: Applications

Robotic arms are typically used for industrial applications. The application is the type of work robot is designed to do. Different applications will have different requirements.

For example, a painting robot will require a small payload but a large movement range. On the other hand, an assembly robot will have a small workspace but will be very precise and fast. Industrial robots are designed for specific applications and based on their function will have their own movement, linkage dimension, control law, software and accessory packages. Below are some types of applications:

• Welding Robot

• Material Handling Robot

• Palletizing Robot

• Painting robot

• Assembly Robot

• Space borne applications

• Pick and place

• Drilling

1.4 ADVANTAGES AND DISADVANTAGES

Advantages:

• Low Cost

• Helpful for disabled person

• Has 6 degrees of freedom

• Can be easily controlled by your mobile phone

Disadvantages :

• Complex circuitry

• Requires an app for functioning

• May affect the human jobs

2: PROJECT DESIGN

It is the second part of our project design in this part we will try to understand backend mechanism of robotic arm and its control diagram

2.2 Robotic Arm Assembly:

It will be consisting of a 3D printed robotic arm with servo motors for its motion. We will be

using 6 servo motors one for the base rotation , one will be ensuring the up/down movement

of shoulder , one for movement of elbow joint and the last one will be used for the gripping

action of the arm

2.3 Circuit Design:

• This Circuit is responsible for the working of the project.

• Digital pins 7,8,9,10,11,12 is used up by the servo motors and 13(TX) and

Analog pin A0(RX) for serial communication.

• We connect the components as shown in the circuit diagram.

• Servo motor usage, S1 -> Waist, S2-> Shoulder, S3-> Elbow, S4-> Wrist Roll

S5-> Wrist Pitch, S6-> Grip. These servo motors are used to drive the robotic arm

3 : Development and implementation

3.1: Flow Control

• Signal is received by the microcontroller and it computes accordingly which

component is to be controlled.

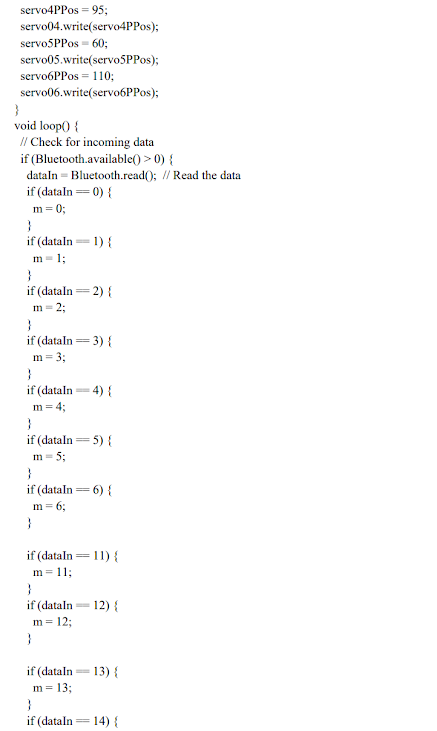

3.2 Programming

• #include is used to operate the servo using servo related functions.

• Servos are initialized to the pin as, S1 to 12, S2 to 11, S3 to 10, S4 to 9, S5 to

8 and S6 to 7 .

• Also we have initialized the initial positions of the servos in the variables

servo1Pos, servo2Pos, servo3Pos, servo4Pos, servo5Pos, servo6Pos.

• In void setup() we have set the baudrate to 9600 for serial communication

with object

• In void loop(), we write the initial positions of the servos.

• if(serial. Available()>0) is used to reject the garbage values <0.

• We have set some constraints for the ‘pos’ variables in the if loop because of

some mechanical limitations of the arm. These values were found by trial and error.

• Then according to the condition, we have called the appropriate functions and

for the movements we have incremented or decremented by 10.

• We are using a do-while loop in the robotic arm mode so that it would remain

in that mode unless ‘1’ is pressed again on the app.

4:Conclusion and Scope

4.1 CONCLUSION

We have made a robotic arm in this project. This robotic arm is able to pick and place objects.

It has 6 degrees of freedom of movement, we’ve performed a simple task of picking a paper

ball from one end of the table and putting it back to the other end of table and we’ve done this

with the help of an arm controlling app as shown above.

4.2 FUTURE SCOPE

We can add extra control options in this project like controlling it through human gestures or

make it completely autonomous by adding a recording option so that for particular

movements it can operated without a user. We can add mobility to this project by adding car

chassis. With the addition of object recognition using image processing and ultrasonic sensor,

this robot could be automated so that there won’t be any need of it to be manually controlled,

it could be programmed in such a way that it would be able to scan and recognize a certain

object in front of it and even remember its location.